The aluminum cup business is growing strongly as businesses focus on sustainable, recyclable, and durable substitute options for plastic cups. There is growing demand from the food service, hospitality, and beverage industries, for which manufacturers make investments in customized, corrosion-free, and light-weight aluminium cups. Businesses deploy automation, quality control based on AI, and green production processes to ensure greater efficiency and conformity to regulations.

Industry players focus on recyclable aluminium, light weight construction, and precision manufacturing to add sustainability and functionality. The industry is moving towards plastic-free, reusable, and customization-friendly aluminium cups to deliver improved user experience and environmental harmony.

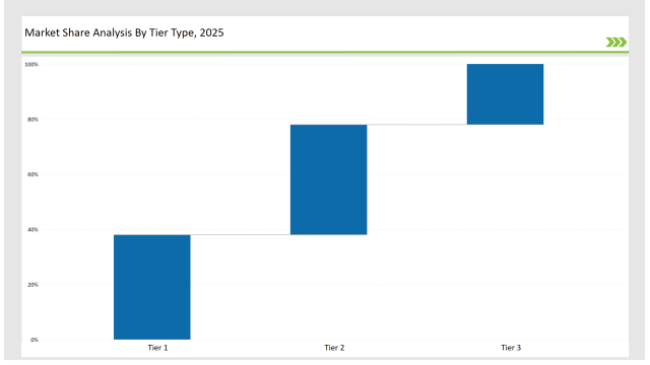

Tier 1 players like Ball Corporation, Trivium Packaging, and Crown Holdings dominate 38% of the market by using large-scale production, cutting-edge manufacturing technologies, and worldwide distribution networks.

Tier 2 companies like Enviro-Cup, Novelis, and WinCup maintain 40% market share with a concentration on customization, sustainability, and high-efficiency manufacturing.

Tier 3 operators, which include regional and niche companies, account for 22% of the market, with specializations in new-generation coatings, customized branding, and intelligent cup solutions.

Explore FMI!

Book a free demo

Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Ball Corporation, Trivium Packaging, Crown Holdings) | 16% |

| Rest of Top 5 (Enviro-Cup, Novelis) | 13% |

| Next 5 of Top 10 (WinCup, Ardagh Group, Alcoa, Hydro, Silgan Holdings) | 9% |

The aluminium cup market caters to various industries where sustainability, durability, and branding are critical. Businesses incorporate intelligent forming methods and AI-based production monitoring to improve product quality and conformity. Producers create sophisticated coatings to enhance corrosion resistance and increase product life. Businesses use laser engraving technology to facilitate accurate branding and customization. Businesses use AI-based supply chain analytics to streamline logistics and minimize waste. Industry experts invest in light alloy formulations to increase strength while reducing material consumption.

Producers develop aluminium cup technology with protective coatings, tamper-evident designs, and AI-enabled manufacturing processes. AI-assisted defect detection improves quality assurance and reduces material loss. Companies develop anti-microbial finishes to deliver higher hygiene and safety for beverage applications. Companies integrate automated quality control mechanisms to minimize defects and ensure consistency. Businesses seek biodegradable aluminium solutions to promote sustainability initiatives. Industry leaders use advanced forming technologies to maximize structural integrity and weight reduction.

Companies accelerate aluminium cup innovations by adopting high-precision forming, AI-powered defect detection, and recyclable coatings. They refine lightweight yet strong designs to enhance sustainability and product durability. Industry leaders implement advanced branding technologies to provide customizable, laser-engraved designs. Manufacturers integrate automated production systems to improve efficiency and reduce material waste. Firms develop high-performance coatings to enhance durability and resistance to extreme temperatures. Businesses explore smart cup technology to enable real-time consumer engagement. Companies invest in AI-driven material optimization to reduce costs and improve product performance. Industry leaders advance laser-cutting techniques to enhance precision and customization options. Manufacturers implement blockchain tracking to improve supply chain transparency and authenticity.

Year-on-Year Leaders

Technology suppliers should prioritize sustainability, automation, and branding features to drive market growth. Collaborating with beverage, hospitality, and sports industries will foster innovation and adoption. Companies should invest in AI-driven production monitoring to enhance quality control. Manufacturers must develop lightweight aluminium alloys to improve strength and reduce material costs. Firms should implement digital tracking systems to optimize supply chain transparency. Businesses need to enhance automated quality control processes to minimize defects and improve consistency.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Ball Corporation, Trivium Packaging, Crown Holdings |

| Tier 2 | Enviro-Cup, Novelis, WinCup |

| Tier 3 | Ardagh Group, Alcoa, Hydro, Silgan Holdings |

Leading manufacturers enhance AI-driven production, sustainable coatings, and smart branding technology. They integrate lightweight, tamper-proof features to improve safety and durability. Companies develop cloud-based defect detection systems to optimize manufacturing efficiency. Firms implement machine learning algorithms to improve defect prediction and minimize waste. Manufacturers integrate robotics to streamline production and enhance precision. Businesses adopt sustainable sourcing practices to reduce environmental impact. Companies leverage big data analytics to optimize material usage and cost efficiency.

| Manufacturer | Latest Developments |

|---|---|

| Ball Corporation | Expanded recyclable aluminium cup production (March 2024) |

| Trivium Packaging | Developed lightweight, tamper-proof cups (April 2024) |

| Crown Holdings | Introduced custom laser-engraved branding (May 2024) |

| Enviro-Cup | Released AI-powered quality inspection systems (June 2024) |

| Novelis | Innovated temperature-controlled, sustainable cups (July 2024) |

| WinCup | Strengthened corrosion-resistant aluminium coatings (August 2024) |

| Ardagh Group | Enhanced premium beverage cup production (September 2024) |

The aluminum cup industry advances as businesses invest in automation, intelligent materials, and eco-friendly packaging. Companies apply AI-based defect detection, lightweight materials, and recyclable coatings to enhance product quality and efficiency. Businesses create innovative forming technologies to further structural integrity and minimize the use of materials. Companies use predictive maintenance systems to reduce downtime and enhance operational efficiency. Companies take on high-speed production techniques to raise capacity while upholding quality standards. Industry experts incorporate green energy sources into production processes to reduce carbon impressions.

Manufacturers develop AI-driven customization, ultra-lightweight materials, and tamper-proof packaging. They refine recyclable and biodegradable coatings while integrating IoT-enabled tracking solutions to enhance supply chain transparency and efficiency. Companies implement high-speed forming techniques to increase production output and reduce waste. Firms develop advanced barrier coatings to improve product longevity and resistance to environmental factors. Businesses invest in digital twin technology to simulate and optimize manufacturing processes. Industry leaders incorporate AI-powered defect detection to enhance quality control. Manufacturers integrate predictive maintenance systems to minimize downtime and maximize efficiency. Companies explore self-cleaning aluminium coatings to improve hygiene and usability.

Ball Corporation, Trivium Packaging, Crown Holdings, Enviro-Cup, Novelis, WinCup, Ardagh Group, Alcoa, Hydro, Silgan Holdings.

The top 3 players collectively hold 16% of the global market.

The market shows medium concentration, with top players holding 38%.

The industry's growth is driven by rising demand for sustainable alternatives to plastic, advancements in manufacturing efficiency, increasing regulatory support for eco-friendly packaging, and expanding applications in food service, retail, and hospitality sectors.

Cutter Box Films Market Growth – Demand & Trends Forecast 2025-2035

Disposable Tea Flask Market Trends – Growth & Forecast 2025 to 2035

Stretch Blow Molding Machines Market Segmentation based on Technology Type, Orientation Type, End Use, and Region: A Forecast for 2025 and 2035

Degassing Valves Market Analysis - Growth & Demand 2025 to 2035

Custom Binders Market Growth & Industry Forecast 2025-2035

Corner Pads Market Insights - Growth & Demand 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.