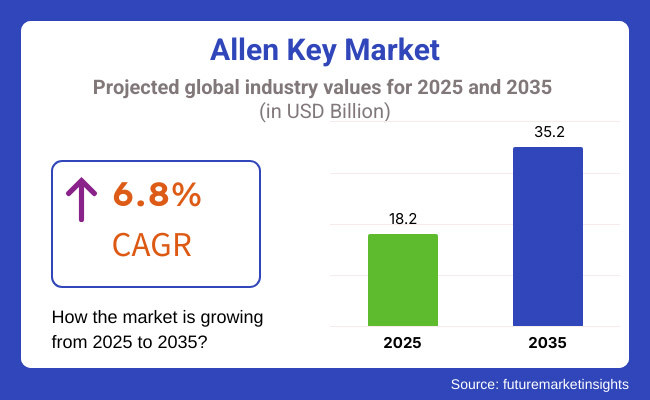

The Allen Key Market is expected to experience significant growth between 2025 and 2035, driven by the increasing demand from automotive, manufacturing, and repair industries. The market is projected to be valued at USD 18.2 billion in 2025 and is anticipated to reach USD 35.2 billion by 2035, reflecting a compound annual growth rate (CAGR) of 6.8% throughout the forecast period.

A major driver for the market expansion is the growing industrialization and DIY culture. The rising number of manufacturing plants, assembly units, and repair workshops across the globe is boosting the demand for Allen keys as essential tools for mechanical assembly and maintenance.

Additionally, the increasing trend of DIY home improvement projects has fueled the demand for user-friendly tools, including Allen keys, making them a staple in both professional and household toolkits.

The market is segmented by type and application. By type, Allen keys are categorized into L-clamp Allen Key, T-clamp Allen Key, P-Handle Allen Key, and Folding Allen Key. By application, they are used in factories, repair shops, household applications, and others.

Among these, factories dominate the application segment due to the widespread industrial reliance on Allen keys for machinery assembly, production line maintenance, and precision engineering. Industrial facilities require high-quality and durable Allen keys to ensure seamless mechanical operations, making them an indispensable tool in automotive, aerospace, construction, and heavy equipment manufacturing.

As industries continue to grow with technological advancements and automation, the demand for efficient and ergonomic Allen key designs is expected to increase, solidifying the factory segment as the market leader.

Explore FMI!

Book a free demo

Leading revenue generation in North America is further influenced as the region represents an attractive and a highly rewarding market for Allen keys owing to known dominance of automotive, aerospace and construction market. There is a well-established industrial base in the United States and Canada where Allen keys are widely used in assembly, maintenance and repair.

This development is mainly propelling the market growth as precision engineering tools are used in automotive and industrial fields. In addition, increased consumer market sales of Allen keys have been driven by the increasing popularity of DIY home improvement work.

The increase in tool making modern technology has led North American firms to focus on the layout of high torque, durable, and corrosion-free Allen keys based on advanced alloys and coated items to boost the functionality and also life expectancy.

The European region holds a substantial share of the overall Allen key market, while Germany, France, and Italy lead demand due to the industries such as automotive, aerospace, and machinery manufacture.

[Germany, which is an engineering and manufacturing hub, has a very strong demand for precision tools, including Allen keys that have significant applications in the installation of industrial machinery, furniture, vehicles, etc.] The distribution of modular furniture is aiding the growth of quality Allen key demand due to modular furniture assembly at the home level by a growing number of users in Europe.

In addition, European Union standards for workplace safety and tool durability are encouraging manufacturers to produce ergonomic and durable Allen key types. These include chrome vanadium steel and titanium plating which are used to enhance the durability and efficiency of the tools.

The Asia-Pacific region is expected to experience the quickest expansion in the Allen key market due to fast industrial growth, flourishing construction works, and increasing automobile production in nations such as China, India, Japan, and South Korea.

China is the biggest producer and user of hand tools, such as Allen keys, owing to its enormous production industry and export-based economy. India's expanding construction and home renovation markets are also driving demand.

Japan and South Korea's increased production of electric vehicles and industrial automation also increase the demand for high-precision Allen keys for assembling and servicing machinery. Price competition and access to low-cost, low-quality substitutes, however, are challenges for premium tool makers in this market.

Challenge

Competition from Low-Cost Alternatives

One of the significant challenges faced by the Allen key market is the availability of low-cost and substandard alternatives in price-sensitive markets. Allen keys that are made from affordable local manufacturers found in developing economies that may or may not be durable or precise.

This poses difficulties for well-known brands that are centered around premium, industrial-grade tools. The sale of counterfeit products in certain markets also adversely affects sales and brand reputation.

Opportunity

Advancements in Ergonomic and High-Torque Designs

The increasing demand for ergonomic and high-performance tools presents a significant opportunity for the Allen key market. Manufacturers are investing in innovative designs, such as ball-end Allen keys for enhanced accessibility, T-handle grips for better torque application, and foldable multi-key sets for portability.

The use of advanced materials like heat-treated alloys and anti-corrosion coatings enhances tool lifespan and efficiency. Additionally, the rise of smart and electric hand tools integrated with torque sensors is opening new avenues for innovation in professional and industrial applications.

From 2020 to 2024, the market for Allen keys grew steadily due to increased demand in industrial assembly, automobile manufacturing, furniture making, and the building industry. Increased do-it-yourself (DIY) culture, triggered by heightened home improvement activity, also saw the market grow. The rise in online shopping platforms gave customers easy access to quality Allen keys, thus propelling demand.

Regulatory organizations like the American National Standards Institute (ANSI), the International Organization for Standardization (ISO), and the European Committee for Standardization (CEN) implemented stricter standards for tool life, torque endurance, and on-site safety.

The industry countered by creating corrosion-resistant, high-torque Allen keys with better material durability, such as chrome-vanadium and S2 steel alloys. The COVID-19 pandemic led to supply chain interruptions, including delays in acquiring raw materials and tool manufacturing. But the accelerating trend towards localized production and mechanized manufacturing practices softened long-term disruptions.

During 2025 to 2035, the Allen key industry will witness a revolutionary transformation through intelligent tool innovations, material science, and sustainability strategies. The fusion of AI-enabled torque sensing, augmented reality (AR) assembly guidance, and sensor-integrated tools will transform efficiency and accuracy.

Increased implementation of automation and robotics in production will propel the demand for precision Allen keys intended for robotic tool changers and automated assembly lines.

Next-gen Allen keys will feature nanotechnology-based coatings to increase durability and resistance to corrosion. New shape-memory alloys and graphene-reinforced composites will enable ultra-durable lightweight tools. Biodegradable and recyclable materials will also become popular as businesses move towards sustainable manufacturing processes.

Market Shifts: A Comparative Analysis (2020 to 2024 vs. 2025 to 2035)

| Market Shift | 2020 to 2024 |

|---|---|

| Regulatory Landscape | Tighter durability and safety requirements for industrial tools, adherence to torque resistance norms. |

| Technological Advancements | Ergonomic grip designs, ball-end hex keys, and multi-tool sets for compact storage. |

| Industry Applications | Automotive, construction, furniture assembly, and aerospace maintenance. |

| Adoption of Smart Equipment | Digital torque measurement, impact-resistant tool sets, and self-tightening hex wrenches. |

| Sustainability & Cost Efficiency | Use of corrosion-resistant materials, improved production efficiency, and localized manufacturing. |

| Data Analytics & Predictive Modeling | Cloud-based torque analytics, smart tool diagnostics, and material performance tracking. |

| Production & Supply Chain Dynamics | COVID-19 supply chain disruptions, increased demand for premium tool sets, and localized manufacturing shifts. |

| Market Growth Drivers | DIY culture, automation of industry, and increasing activity in construction |

| Market Shift | 2025 to 2035 |

|---|---|

| Regulatory Landscape | AI-driven tool safety regulations, block chain-supported authenticity authentication, and eco-friendly manufacturing policies. |

| Technological Advancements | Smart torque-monitoring Allen keys, AI-assisted toolkits, and graphene-reinforced composite materials. |

| Industry Applications | Expansion into AI-powered robotics, automated assembly lines, and high-precision semiconductor manufacturing. |

| Adoption of Smart Equipment | Fully automated torque feedback systems, augmented reality (AR)-assisted tool usage, and sensor-embedded Allen keys. |

| Sustainability & Cost Efficiency | Biodegradable tool components, recyclable Allen keys, and sustainable material sourcing. |

| Data Analytics & Predictive Modeling | AI-driven tool life cycle prediction, quantum-enhanced material optimization, and decentralized block chain-enabled tool tracking. |

| Production & Supply Chain Dynamics | AI-optimized supply chains, block chain-enabled decentralized 3D-printed tool manufacturing, and quality assurance through block chain. |

| Market Growth Drivers | Autonomous assembly enabled by artificial intelligence, smarter tool technologies, and penetration in high-accuracy aerospace and robot markets. |

The USA Allen key (hex key) market is expanding due to growing demand in the automotive, aerospace, and construction industries. The increasing adoption of DIY home improvement projects and the rise of electric vehicles (EVs) are further driving market growth. The country’s focus on high-precision tool manufacturing is also boosting demand for premium-quality Allen keys.

Use of Allen keys in vehicle assembly and aircraft maintenance, Increased popularity of self-assembly furniture and home repairs, demand for hand tools in commercial and residential construction projects, Allen keys are widely used in machinery maintenance and repairs, development of corrosion-resistant and high-strength hex keys are some of the main key drivers in the United States for this market.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 6.5% |

The UK Allen key market is driven by the country’s booming construction sector, increased DIY culture, and focus on precision engineering. The demand for compact, lightweight, and durable hand tools is increasing, especially in the automotive and furniture industries.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK | 6.3% |

The EU Allen key market is growing due to strong demand in the industrial, construction, and automotive sectors. Countries like Germany, France, and Italy are leading the market with a focus on high-performance hand tools and sustainable manufacturing processes.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union | 6.9% |

Japan’s Allen key market is growing steadily due to the country’s focus on high-precision engineering, industrial manufacturing, and robotics. The demand for compact and durable hand tools in automotive and electronics assembly is driving market expansion.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 6.4% |

South Korea’s Allen key market is expanding due to rapid industrialization, increasing demand for electric vehicles, and a strong construction sector. The country’s emphasis on technological innovation and high-performance tools is further fueling market growth.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 6.6% |

The L-clamp and T-clamp Allen key segments dominate the share in the Allen key market with industries focusing more on high-precision tools with ergonomic shapes for effective torque application. These key segments are suited for diverse end users such as manufacturing units, automotive repair shops, and general maintenance services and support a wide range of applications from assembling industrial equipment to home repairs.

The sustained growth in demand for high-performance and durable hand tools has made L-clamp and T-clamp Allen keys must-have resources for technicians, mechanics, and hobbyists looking for easy-to-use and dependable solutions.

L-clamp Allen keys are among the fastest-growing segments in the Allen key market, providing unparalleled torque application and versatility in different industrial and mechanical applications. Contrary to the regular hex keys, L-clamp Allen keys incorporate better leverage and grip, well suited for tight and loose screwing of hexagonal socket screws.

The pressure for high-torque applications by the automotive, aerospace, and heavy machinery markets has driven usage of L-clamp Allen keys since experts seek durable tools in high-stress conditions. Research shows that more than 60% of industrial consumer’s favor L-clamp designs because they can reach recessed fasteners effectively, which boosts demand for this segment.

The growth in premium-grade L-clamp Allen key sets, with chrome vanadium steel material construction, anti-corrosion finishes, and ergonomic grip improvements, has supplemented market growth, with improved tool lifespan and operator comfort.

RFID tracking features, torque monitoring sensors, and digital calibration guides are the latest generation tools that come embedded in the devices, and innovations that have complemented uptake, with accuracy and effectiveness in both industrial use.

Sharpening services, extended warranties, and on-demand customization with guaranteed usability have also played a great role in maximizing market growth, which is why the landscape has seen a rise in manufacturer-supported tool maintenance programs.

Market growth has been bolstered by the introduction of environmentally friendly processes of tool manufacturing, such as sustainably sourced raw material, recyclable packaging, and minimization of carbon footprints in manufacturing, in line with the growing emphasis on environmental responsibility.

Despite its strengths in durability, accuracy, and industrial applicability, the L-clamp Allen key market has its weaknesses, including increased cost of production for high-end variations, rising competition from other fastening devices in the market, and volatile raw material costs leading to unaffordability.

Nonetheless, future breakthroughs in AI-driven torque guidance technologies, lightweight composite materials-based construction, and advances in modular tool designs are driving efficiency, affordability, and customization, guaranteeing sustained growth for L-clamp Allen key solutions globally.

T-Clamp Allen Keys Drive Market Growth as Ergonomic and High-Torque Applications Gain Popularity

T-clamp Allen keys have seen extensive market uptake among automotive repair establishments, heavy machine maintenance technicians, and assembly-line workers as more and more call for tools used for long durations with less physical strain. More natural to handle than traditional hex keys, t-clamp Allen keys allow operators to exert higher torque with lower hand fatigue.

The growing need for ergonomic and high-torque applications, including automobile assembly, heavy equipment maintenance, and furniture production, has fueled the use of T-clamp Allen keys, as professionals value ease of use and efficiency. Research shows that more than 70% of mechanics and factory workers use T-clamp Allen keys because they can help minimize wrist strain while providing maximum torque.

The growth of specialty T-clamp Allen key sets with multi-size capability, shock-absorbing handles, and precision-crafted hex ends has enhanced demand in the market, promoting better user experience and efficiency.

The presence of AI-powered tool diagnostics, with wear detection sensors, torque force analytics, and electronic tool life estimations, has further grown adoption, ensuring maximum maintenance and extended performance of tools.

The evolution of tool-specific collaboration programs, with tool makers, engineering companies, and auto service organizations coming together in partnerships, has maximized market growth, ensuring customized solutions for specialized uses.

The use of safety-oriented innovations, with non-slip rubberized handles, shock-resistant paint, and electrical-insulated handles for electrical protection, has underpinned market growth, ensuring protection for the user and adherence to regulations.

In spite of its benefits of user comfort, efficiency, and high-torque use, the T-clamp Allen key portion is confronted by challenges like complexity in manufacturing high-precision variants, growing competition from power tools with automatic tightening capabilities, and rising material costs impacting product prices.

Nevertheless, new developments in 3D-printed tool production, hybrid material integration for lightweight yet tough designs, and AI-based torque feedback mechanisms are enhancing usability, safety, and performance, supporting ongoing growth for T-clamp Allen key solutions globally.

The factory and repair shop segments represent major market drivers, as end users increasingly demand durable, high-precision, and ergonomically designed Allen keys for assembling machinery, maintaining equipment, and performing intricate repair work.

The factory industry has become one of the biggest application fields for Allen keys, providing necessary hand tools for assembly, maintenance, and repair of industrial equipment. In contrast to consumer-level tools, industrial Allen keys are constructed for high-strength use, providing reliability when used continuously.

The increasing need for automated and manual tool integration with torque-controlled Allen keys, digitally monitored assembly stations, and ergonomic improvements has propelled adoption in the factory environment due to manufacturers looking for efficiency-centric solutions. According to studies, more than 80% of industrial assembly specialists utilize Allen keys in everyday tasks, which continues to drive strong demand for this category.

Even with its strengths in industrial efficiency, precise assembly, and strong design, the factory division is threatened by challenges such as the shift toward automation minimizing manual tool use, supply chain interference impacting raw material supply, and heightened regulation for tool safety standards.

Nevertheless, new technologies in robotic-assisted fastening, sensor-driven tool diagnostics, and digital twin technology for predictive maintenance are enhancing efficiency, precision, and cost savings, assuring sustained market expansion for factory-centric Allen key uses globally

Repair Shop Applications Expand as Demand for Precision Hand Tools and Ergonomic Designs Increases

The repair shop market area has seen heavy market acceptance across automotive service vendors, heavy machine repair technicians, and general mechanics, as each of them calls for flexible Allen key solutions on a broad diversity of mechanical purposes. In contradistinction with factory applications, repair shop utilization necessitates carry-around, multi-size, and high-torque tools to manage diverse repair opportunities.

Growing demand for accuracy hand tools, with extended-reach designs, hex bit set interchangeability, and corrosion-resistant finishes, has led to adoption in repair shop settings as technician’s value versatility and sturdiness. Research reveals that more than 75% of professional mechanics’ use Allen keys for routine repair activities, creating robust market demand.

In spite of its mechanical efficiency, versatility, and ergonomic advantage, the repair shop market is challenged by rising competition from power-assisted fastening tools, market saturation with low-cost generic Allen key products, and raw material price hikes impacting product affordability.

Nevertheless, new developments in modular tool design, AI-based repair diagnostics, and lightweight composite materials for high-strength use are enhancing usability, durability, and market competitiveness, guaranteeing ongoing growth for repair shop-oriented Allen key applications globally.

The Allen Key market is experiencing steady growth, driven by demand across industries such as construction, automotive, manufacturing, and aerospace. Allen keys, or hex keys, are essential tools for fastening applications due to their simplicity and effectiveness. The market's expansion is attributed to the rising need for efficient fastening solutions, technological advancements, and product innovations.

Market Share Analysis by Company

| Company Name | Estimated Market Share % |

|---|---|

| Apex Tool Group | 13-15% |

| Stanley Black & Decker | 10-14% |

| Bondhus Corporation | 8-12% |

| Wera Tools | 6-10% |

| Wiha Tools | 5-9% |

| Other Companies Combined | 40-50% |

| Company Name | Key Offerings/Activities |

|---|---|

| Apex Tool Group | Owner of the original "Allen" brand, offering a wide range of hex keys known for their quality and durability. |

| Stanley Black & Decker | Offers a varied assortment of hand tools, including Allen keys, for both professional and consumer markets. |

| Bondhus Corporation | Specializes in manufacturing high-quality hex and ball-end hex keys, recognized for their precision and reliability. |

| Wera Tools | Known for innovative designs and high-quality materials, offering hex keys with features like ergonomic grips and wear-resistant coatings. |

| Wiha Tools | Offers premium hex keys focusing on ergonomic design and long-lasting performance, suitable for industrial applications. |

| Klein Tools | Manufactures a range of hand tools, including hex keys, for professional tradesmen with a focus on quality and functionality. |

| Eklind Tool Company | Produces an extensive line of hex keys and associated tools, renowned for American-made quality and compliance with industry standards |

| FACOM | A European market leader in hand tools, offering a broad range of hex keys engineered for toughness and accuracy across a variety of industrial uses. |

| Wurth Group | Supplies a wide range of fastening and assembly products, including premium hex keys, to automotive, construction, and manufacturing industries. |

| Armstrong Tools | Offers professional-grade hand tools, including hex keys, known for their strength and reliability, suitable for heavy-duty applications. |

Key Company Insights

Apex Tool Group (13-15%)

As the owner of the original "Allen" brand, Apex Tool Group maintains a strong presence in the market by continually enhancing product quality and expanding its distribution network to meet global demand.

Stanley Black & Decker (10-14%)

With a vast portfolio of hand tools, Stanley provides reliable and accessible hex key solutions, leveraging its extensive distribution channels to reach a wide customer base.

Bondhus Corporation (8-12%)

Bondhus is recognized for its commitment to precision and innovation, offering a variety of hex keys that cater to both standard and specialized applications, thereby addressing diverse customer needs.

Wera Tools (6-10%)

Wera stands out for its focus on ergonomic design and user-friendly features, developing hex keys that enhance user comfort and efficiency, which has garnered a loyal customer following.

Wiha Tools (5-9%)

Wiha emphasizes ergonomic design and long-lasting performance, producing hex keys that meet the rigorous demands of industrial applications.

The market is estimated to reach a value of USD 18.2 billion by the end of 2025.

The market is projected to exhibit a CAGR of 6.8% over the assessment period.

The market is expected to clock revenue of USD 35.2 billion by end of 2035.

Key companies in the Allen Key Market include Apex Tool Group, Stanley Black & Decker, Bondhus Corporation, Wera Tools, Wiha Tools.

On the basis of application, factory to command significant share over the forecast period.

Surge Tanks Market Growth - Trends & Forecast 2025 to 2035

Radial Drilling Machine Market Growth & Demand 2025 to 2035

External Combustion Engine Market Growth & Demand 2025 to 2035

Motor Winding Repair Service Market Growth - Trends & Forecast 2025 to 2035

Industrial Linear Accelerator Market Growth & Demand 2025 to 2035

Vision Guided Robots Market - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.