The airless pumps market is expanding fast as businesses create sustainable, high-precision, and tamper-proof dispensing systems. With growing demand from personal care, pharmaceutical, and food industries, manufacturers emphasize durability, cleanliness, and effective product dispensing. Businesses incorporate automation, AI-based quality control, and recyclable materials to maximize production and comply with regulatory requirements.

Industry pioneers focus on the use of green materials, leak-proof construction, and high-accuracy dosing systems to advance product functionality and sustainability. The industry is trending toward lightweight, customizable, and air-tight airless pumps that enhance user convenience and increase product shelf life.

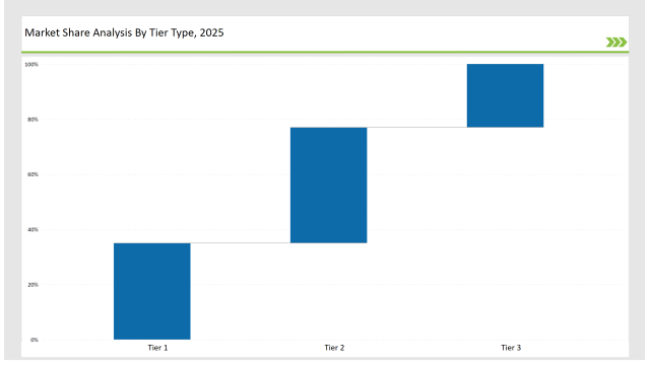

Tier 1 companies like AptarGroup, Silgan Dispensing, and Albea Group hold 35% of the market share through superior manufacturing, innovative technology, and international distribution channels.

Tier 2 players such as Lumson, Quadpack, and FusionPKG account for 42% market share, with an emphasis on customization, sustainability, and efficient production.

Tier 3 players, made up of regional and niche players, account for 23% of the market, with expertise in refillable solutions, precision dispensing, and eco-friendly packaging options.

Explore FMI!

Book a free demo

| Category | Market Share (%) |

|---|---|

| Top 3 (AptarGroup, Silgan Dispensing, Albea Group) | 15% |

| Rest of Top 5 (Lumson, Quadpack) | 13% |

| Next 5 of Top 10 (FusionPKG, Raepak, RPC Bramlage, Yonwoo, Toly) | 7% |

The airless pumps business caters to various industries that require hygiene, accuracy, and eco-friendliness. Firms adopt AI-based defect detection and intelligent dispensing technology to enhance product performance and address customer needs. Pump efficiency is optimized by the makers through fluid dynamics to ensure smoother dispensing. Energy-efficient manufacturing processes are adopted to minimize carbon footprint. Companies create antimicrobial coatings to promote hygiene and avoid contamination.

Manufacturers improve airless pump solutions with biodegradable components, tamper-evident designs, and AI-based manufacturing methods. AI-based quality control improves consistency and minimizes material waste. Businesses incorporate automated assembly lines to optimize production and enhance efficiency. They implement predictive analytics to predict maintenance requirements and minimize downtime. Companies create modular pump parts to make repairs easier and maximize product life. Manufacturers improve pump looks with customizable finishes and branding capabilities. Businesses use intelligent packaging solutions to enhance user experience and product traceability. Companies design high-pressure airless pumps to enhance dispensing efficiency.

Companies accelerate airless pump innovations by adopting high-precision molding, AI-powered defect detection, and refillable packaging solutions. They refine lightweight yet durable designs to enhance sustainability and product efficiency. Industry leaders implement smart dispensing technology to improve consumer experience and product application. Manufacturers optimize material selection to enhance durability and reduce production costs. They integrate machine learning to predict user preferences and customize dispensing mechanisms. Firms create airless pumps with improved barrier protection to increase product shelf life. Companies invest in sophisticated automation to reduce production complexity and boost output. Companies use environmentally friendly coatings to enhance recyclability and comply with regulations.

Technology vendors must prioritize sustainability, automation, and customization for market growth. Having personal care, pharmaceutical, and food industry partnerships will stimulate innovation and uptake. Companies need to use AI-based forecasting to optimize material procurement. They should develop advanced sensor technology to enhance real-time quality control.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | AptarGroup, Silgan Dispensing, Albea Group |

| Tier 2 | Lumson, Quadpack, FusionPKG |

| Tier 3 | Raepak, RPC Bramlage, Yonwoo, Toly |

Leading manufacturers enhance AI-driven production, refillable designs, and smart dispensing technology. They integrate lightweight, tamper-proof features to improve safety and durability. Companies develop cloud-based defect detection systems to optimize manufacturing efficiency. Firms implement machine learning algorithms to predict and prevent quality defects. Businesses invest in biodegradable materials to align with global sustainability goals. Companies enhance automation in production lines to increase output and maintain precision.

| Manufacturer | Latest Developments |

|---|---|

| AptarGroup | Expanded sustainable airless pump production (March 2024) |

| Silgan Dispensing | Developed tamper-resistant dosing pumps (April 2024) |

| Albea Group | Introduced custom ergonomic designs (May 2024) |

| Lumson | Released AI-powered defect detection (June 2024) |

| Quadpack | Innovated smart refillable technology (July 2024) |

| FusionPKG | Strengthened lightweight, recyclable pump manufacturing (August 2024) |

| Yonwoo | Enhanced luxury skincare airless packaging (September 2024) |

The airless pumps market evolves as companies invest in automation, sustainable materials, and smart dispensing. Companies incorporate AI-based defect detection, light-weight materials, and accurate dosing mechanisms to enhance product efficiency and safety. Companies use AI-based analytics for streamlining production processes. They increase supply chain transparency with the help of blockchain technology. Businesses create refillable airless pump solutions in an effort to lower plastic waste.

Manufacturers create AI-based customization, ultra-lightweight materials, and tamper-evident packaging. They optimize recyclable and biodegradable pumps and incorporate IoT-enabled smart dispensing solutions to improve functionality and minimize waste. Companies optimize production efficiency by embracing high-speed molding processes. They use AI-based predictive maintenance to reduce downtime and improve operational efficiency. Companies use sustainable raw materials to minimize environmental footprint. Businesses optimize sealing technologies to avoid leakage and increase product shelf life. Producers streamline ergonomic design for maximum user comfort and ease of dispensing. Firms incorporate intelligent sensors to monitor and assure quality in real time. Industry leaders develop refillable pump systems to support circular economy initiatives.

AptarGroup, Silgan Dispensing, Albea Group, Lumson, Quadpack, FusionPKG, Raepak, RPC Bramlage, Yonwoo, Toly.

The top 3 players collectively hold 15% of the global market.

The market shows medium concentration, with top players holding 35%.

Companies are focusing on refillable packaging, AI-driven quality control, and sustainable materials to meet growing consumer and regulatory demands.

Europe Flexible Plastic Packaging Market Analysis by Material, Product Type, End Use, Packaging Type, and Region Forecast Through 2035

Personal Care Packaging Market Analysis by Application, Packaging Format, Capacity, and Region Forecast Through 2035

Bottle Capping Machine Market Analysis by Automation, Operating Speed, Machine Type, End-use Industry, and Region Forecast Through 2035

Market Share Breakdown of Alu Alu Blister Packaging Machine Industry

Market Share Breakdown of Tablet Packing Machine Industry

Market Share Breakdown of Algae-Based Bioplastics Industry

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.