The air cushion machine industry is expanding rapidly as companies develop efficient, cost-effective, and sustainable protective packaging solutions. With growing demand from e-commerce, logistics, and manufacturing sectors, manufacturers focus on compact, high-speed, and eco-friendly machines. Companies integrate automation, AI-driven predictive maintenance, and biodegradable film materials to enhance efficiency and sustainability.

Industry leaders prioritize lightweight designs, customizable air pillow solutions, and smart packaging integration to improve performance and reduce environmental impact. The market is shifting toward energy-efficient, automated, and IoT-enabled air cushion machines that enhance packaging operations and optimize material usage.

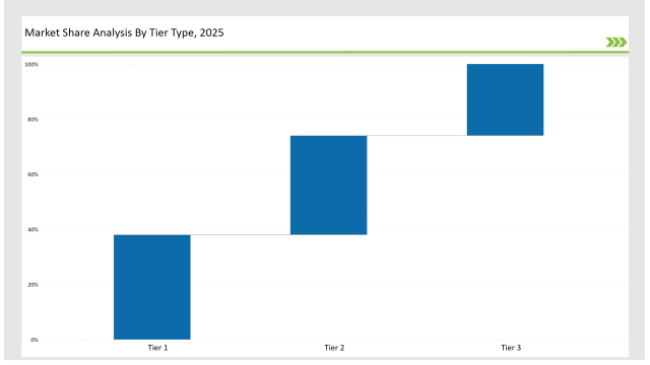

Tier 1 players such as Sealed Air, Pregis, and Storopack control 38% of the market by leveraging global distribution networks, cutting-edge technology, and large-scale production capabilities.

Tier 2 players including Airspeed, FP International, and Mini Air hold 36% market share, focusing on compact, on-demand packaging systems and cost-effective film solutions.

Tier 3 players, consisting of regional and niche firms, contribute 26% of the market, specializing in customized cushioning solutions, biodegradable air pillows, and smart packaging technologies.

Explore FMI!

Book a free demo

| Category | Market Share (%) |

|---|---|

| Top 3 (Sealed Air, Pregis, Storopack) | 16% |

| Rest of Top 5 (Airspeed, FP International) | 14% |

| Next 5 of Top 10 (Mini Air, AirWave, Ranpak, Freepack, Inflatable Packaging Inc.) | 8% |

The air cushion machine market addresses various industries where protection packaging, sustainability, and performance efficiency matter. Businesses incorporate AI-based monitoring, high-efficiency compressors, and recyclable materials to enhance the performance of the packaging and reduce waste. Businesses use automated quality control to increase consistency and minimize defects. Businesses use biodegradable films to comply with environmental regulations. Firms develop modular air cushion systems to provide flexible and scalable solutions.

Manufacturers refine air cushion machine solutions with biodegradable films, AI-enabled diagnostics, and variable air pressure controls. Automated production lines enhance efficiency and consistency in protective packaging. Companies integrate real-time monitoring to detect inconsistencies and optimize performance. They adopt smart sensors to adjust air pressure automatically for different packaging needs. Manufacturers improve sealing mechanisms to increase durability and prevent leakage.

Companies accelerate air cushion machine advancements by adopting AI-driven defect detection, IoT-enabled operational tracking, and high-speed inflation technology. They refine lightweight yet durable materials to enhance sustainability and packaging integrity. Industry leaders implement automated refilling systems to streamline packaging workflows. Manufacturers develop advanced sealing techniques to improve air retention and reduce leakage. Companies integrate predictive maintenance to minimize downtime and extend machine lifespan. Firms invest in energy-efficient motors to optimize power consumption and enhance sustainability. Businesses adopt modular design frameworks to allow easy customization and upgrades. Industry leaders explore hybrid cushioning materials to improve protection and reduce material waste.

Technology suppliers should focus on sustainability, automation, and smart packaging solutions to drive market growth. Collaborating with e-commerce, logistics, and electronics industries will foster innovation and adoption. Companies should develop AI-driven analytics to optimize material usage and minimize waste. They must enhance machine adaptability to accommodate various packaging needs across industries.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Sealed Air, Pregis, Storopack |

| Tier 2 | Airspeed, FP International, Mini Air |

| Tier 3 | Ranpak, Freepack, AirWave, Inflatable Packaging Inc. |

Leading manufacturers enhance AI-driven quality control, sustainable materials, and automated refilling systems. They integrate lightweight, recyclable designs to improve efficiency and eco-friendliness. Companies develop cloud-based performance monitoring to optimize packaging operations. Firms implement predictive analytics to detect maintenance needs and reduce downtime. Manufacturers improve film sealing techniques to enhance durability and air retention. Companies adopt energy-efficient components to lower operational costs and environmental impact.

| Manufacturer | Latest Developments |

|---|---|

| Sealed Air | Expanded biodegradable air cushion production (March 2024) |

| Pregis | Launched energy-efficient air cushion machines (April 2024) |

| Storopack | Introduced IoT-enabled operational tracking (May 2024) |

| Airspeed | Released compact, on-demand air cushion solutions (June 2024) |

| FP International | Innovated compostable air pillow materials (July 2024) |

| Mini Air | Developed variable air pressure control technology (August 2024) |

| Ranpak | Strengthened recyclable film production (September 2024) |

The air cushion machine market evolves as companies invest in automation, eco-friendly materials, and smart packaging. Firms integrate AI-powered diagnostics, lightweight cushioning materials, and automated defect detection to improve product efficiency and sustainability. Companies develop high-speed inflation systems to reduce processing time. They implement advanced sensors to ensure precise air pressure control. Manufacturers enhance durability by incorporating reinforced film materials.

Manufacturers develop AI-enhanced material optimization, ultra-lightweight air pillows, and fully automated inflation systems. They refine biodegradable packaging solutions while integrating IoT-powered real-time monitoring to enhance efficiency and reduce waste. Companies implement machine learning algorithms to predict material failures and enhance durability. They adopt robotic assembly lines to streamline production and reduce operational costs. Manufacturers explore the use of alternative bio-based films to replace traditional plastics. Firms integrate blockchain technology to improve supply chain transparency and prevent counterfeiting. Industry leaders develop next-generation inflation technology to optimize air distribution and cushioning performance. Companies invest in modular machine designs to enhance scalability and adaptability across different industries.

Sealed Air, Pregis, Storopack, Airspeed, FP International, Mini Air, Ranpak, Freepack, AirWave, Inflatable Packaging Inc.

The top 3 players collectively hold 16% of the global market.

The market shows medium concentration, with top players holding 38%.

The increasing growth of e-commerce, demand for sustainable packaging solutions, and advancements in automation drive the adoption of air cushion machines across industries.

Europe Sharps Container Market Analysis by Usage, Capacity, End Use, and Region Forecast Through 2035

Europe Flexible Plastic Packaging Market Analysis by Material, Product Type, End Use, Packaging Type, and Region Forecast Through 2035

Personal Care Packaging Market Analysis by Application, Packaging Format, Capacity, and Region Forecast Through 2035

Market Share Breakdown of Algae-Based Bioplastics Industry

Market Share Breakdown of Algae Ink Industry

Market Share Breakdown of Alcohol Packaging Industry

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.