The aerosol valves industry is booming as companies are coming up with effective, sustainable and precision dispensing solutions that so far have been fast growing. The demand is increasing in personal care, pharmaceutical, and industrial sectors, and thus, manufacturers are concentrating on customizable, tamper-proof, and eco-friendly valve designs. Besides this, companies automate, integrate AI-powered quality control, and utilize advanced materials in optimizing performance while adhering to regulation.

Leaders in the industry have invested in biodegradable materials, smart dispensing technologies, and lightweight designs to improve their efficiency and sustainability. The market is moving towards less emission, high durability, and recyclable aerosol valves that tend to be more convenient for consumers and environmental authorities alike.

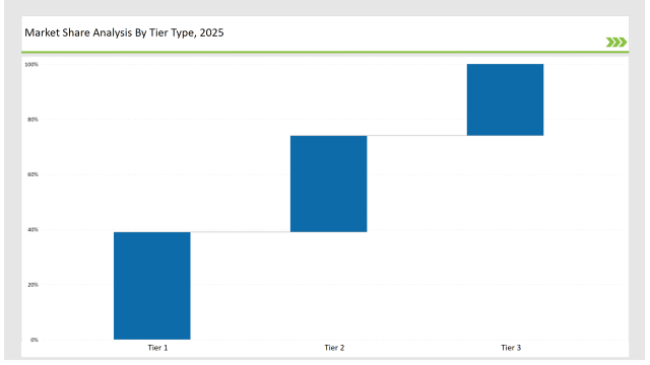

Tier 1 players such as Precision Valve Corporation, AptarGroup, and Summit Packaging Systems control 39% of the market by leveraging large-scale production, advanced R&D, and global distribution networks.

Tier 2 players, including Coster Group, Lindal Group, and Mitani Valve hold 35% of market share. They encourage development in innovative dispensing mechanisms, gas-saving technologies, and tamper-evident designs.

Tier 3 players, consisting of regional and niche firms, contribute 26% of the market, focusing on eco-friendly materials, smart valves, and unique spray mechanisms.

Explore FMI!

Book a free demo

| Category | Market Share (%) |

|---|---|

| Top 3 (Precision Valve Corporation, AptarGroup, Summit Packaging Systems) | 18% |

| Rest of Top 5 (Coster Group, Lindal Group) | 13% |

| Next 5 of Top 10 (Mitani Valve, KOH-I-NOOR, Majesty Packaging Systems, Newman Green, Clayton Corporation) | 8% |

The aerosol valves industry serves multiple sectors that require precision dispensing, sustainability, and safety. Companies integrate smart valve technologies and AI-driven production monitoring to enhance product quality and performance. Manufacturers develop high-pressure-resistant valves to optimize aerosol dispensing. They refine material compositions to enhance valve durability and reduce leakage risks.

Manufacturers refine aerosol valve solutions with biodegradable materials, tamper-resistant designs, and AI-enhanced production techniques. AI-driven defect detection improves quality control and reduces waste. Companies develop high-precision valve components to enhance dispensing accuracy. They implement rapid prototyping to accelerate innovation and reduce development cycles. Firms integrate smart sensors into valves to monitor and adjust spray performance.

Companies accelerate aerosol valve innovations by adopting precision molding, AI-powered defect detection, and sustainable materials. They refine lightweight yet durable designs to enhance sustainability and performance. Industry leaders implement smart valve technology to improve spray consistency and reduce waste. Manufacturers develop corrosion-resistant coatings to extend valve lifespan. Companies integrate machine learning algorithms to predict and prevent potential valve malfunctions. Firms enhance aerosol valve sealing mechanisms to prevent leaks and maintain product integrity. Manufacturers refine propellant efficiency to reduce environmental impact. Businesses explore hybrid valve technologies to optimize dispensing control and minimize waste.

Technology suppliers should prioritize sustainability, automation, and smart dispensing technologies to drive market growth. Collaborating with personal care, pharmaceuticals, and food industries will accelerate innovation and adoption. Companies should enhance supply chain transparency by integrating blockchain technology into tracking systems.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Precision Valve Corporation, AptarGroup, Summit Packaging Systems |

| Tier 2 | Coster Group, Lindal Group, Mitani Valve |

| Tier 3 | Majesty Packaging Systems, KOH-I-NOOR, Newman Green, Clayton Corporation |

Leading manufacturers enhance AI-driven production, sustainable materials, and smart dispensing technologies. They integrate lightweight, tamper-proof features to improve safety and durability. Companies develop cloud-based defect detection systems to optimize manufacturing efficiency. Manufacturers adopt automated assembly processes to increase production speed and precision. They implement sustainable sourcing strategies to reduce carbon footprints and improve environmental responsibility.

| Manufacturer | Latest Developments |

|---|---|

| Precision Valve Corporation | Expanded sustainable valve production (March 2024) |

| AptarGroup | Launched low-emission, recyclable valves (April 2024) |

| Summit Packaging Systems | Introduced custom spray mechanisms (May 2024) |

| Coster Group | Developed AI-powered defect detection (June 2024) |

| Lindal Group | Released smart dispensing valve solutions (July 2024) |

| Mitani Valve | Strengthened gas-saving, lightweight designs (August 2024) |

| Majesty Packaging Systems | Enhanced pharmaceutical valve safety (September 2024) |

The aerosol valve market evolves as companies invest in automation, smart materials, and sustainable dispensing technologies. Firms integrate AI-driven defect detection, lightweight materials, and tamper-proof features to improve product efficiency and safety. Manufacturers develop high-efficiency valve designs to reduce propellant waste. Companies enhance aerosol valve longevity by optimizing material composition and structural integrity.

Manufacturers develop AI-driven customization, ultra-lightweight materials, and smart dispensing solutions. They refine recyclable and biodegradable valves while integrating IoT-enabled tracking to enhance efficiency and reduce waste. Companies enhance valve performance by optimizing spray consistency and reducing clogging issues. They implement real-time defect detection to minimize production errors and improve quality control. Firms innovate self-cleaning valve technologies to extend product lifespan. Manufacturers integrate advanced pressure regulation mechanisms to ensure precise aerosol dispensing. Businesses adopt 3D printing techniques to accelerate prototyping and customization. Companies leverage predictive analytics to optimize inventory and reduce material wastage.

Precision Valve Corporation, AptarGroup, Summit Packaging Systems, Coster Group, Lindal Group, Mitani Valve, Majesty Packaging Systems, KOH-I-NOOR, Newman Green, Clayton Corporation.

The top 3 players collectively hold 18% of the global market.

The market shows medium concentration, with top players holding 39%.

Companies are focusing on sustainable materials, AI-driven production optimization, and smart dispensing technologies to enhance efficiency and reduce environmental impact.

BOPP Film Market Analysis by Thickness, Packaging Format, and End-use Industry Through 2025 to 2035

Korea Tape Dispenser Market Analysis by Material, Product Type, Technology, End Use, and Region through 2025 to 2035

Japan Heavy-duty Corrugated Packaging Market Analysis based on Product Type, Board type, Capacity, End use and City through 2025 to 2035

Corrugated Board Market Analysis by Material and Application Through 2035

Waterproof Packaging Market Trends - Demand & Industry Forecast 2025 to 2035

Thermochromic Labels Market Insights - Innovations & Growth 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.