The aerosol cap market is growing fast as businesses make advanced, sustainable, and tamper-proof packaging solutions. Personal care, pharmaceutical, and industrial sectors' rising demand pushes manufacturers to highlight lightweight, strong, and customizable caps. Businesses incorporate automation, AI-based quality assurance, and environmental-friendly materials in order to maximize production and comply with regulations.

Industry players focus on biodegradable plastics, tamper-evident designs, and high-accuracy molding to improve product performance and sustainability. The industry is moving towards light-weight, child-resistant, and recyclable aerosol caps that enhance user safety and environmental compatibility.

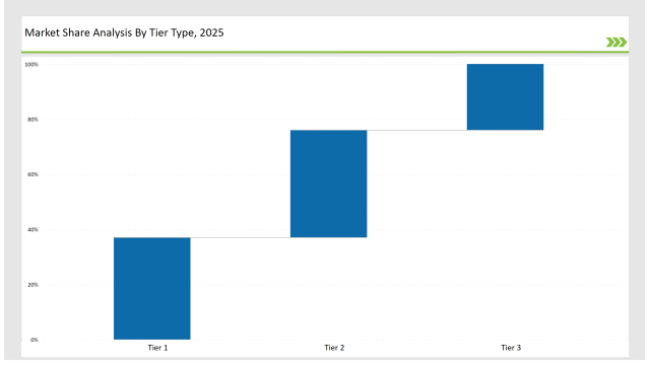

Tier 1 companies like Berry Global, Silgan Holdings, and AptarGroup dominate the market with 37% market share based on large production volumes, sophisticated manufacturing technologies, and international distribution networks.

Tier 2 players such as Precision Valve Corporation, Summit Packaging Systems, and Lindal Group own 39% market share and are concentrating on customization, sustainability, and high-efficiency production.

Tier 3 companies, which are regional and specialty players, make up 24% of the market, and they focus on green materials, intelligent caps, and innovative dispensing systems.

Explore FMI!

Book a free demo

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (Berry Global, Silgan Holdings, AptarGroup) | 17% |

| Rest of Top 5 (Precision Valve Corporation, Summit Packaging Systems) | 12% |

| Next 5 of Top 10 (Lindal Group, Mitani Valve, KOH-I-NOOR Mladá Vožice, Coster Group, Plastipak) | 8% |

The aerosol cap industry serves multiple sectors that require packaging integrity, sustainability, and safety. Companies enhance smart molding techniques and AI-driven production monitoring to improve product quality and ensure compliance. Manufacturers develop tamper-proof designs to increase consumer safety. They optimize material formulations to enhance durability and reduce environmental impact.

Manufacturers refine aerosol cap solutions with biodegradable plastics, tamper-evident designs, and AI-enhanced production techniques. AI-driven defect detection improves quality assurance and reduces waste. Companies enhance cap durability by optimizing material composition. They implement high-speed molding techniques to increase efficiency. Firms develop user-friendly dispensing mechanisms to improve consumer experience.

Companies propel aerosol cap innovation with the use of high-precision molding, AI-based defect detection, and recyclable materials. Companies optimize lightweight and robust designs for higher sustainability and product integrity. Industry players develop intelligent packaging technology to enhance consumer engagement and track product use. Manufacturers design clog-proof designs to extend product life and functionality. Companies employ laser-engraved serial codes to improve product traceability and counterfeiting. Firms optimize material blending techniques to enhance durability while reducing costs. Businesses integrate augmented reality (AR) features into packaging for interactive consumer experiences. Industry leaders explore bio-based coatings to further enhance sustainability efforts.

Year-on-Year Leaders

Technology suppliers should prioritize sustainability, automation, and security features to drive market growth. Collaborating with personal care, pharmaceuticals, and food industries will foster innovation and adoption. Companies should invest in AI-driven production monitoring to enhance quality control and efficiency.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | Berry Global, Silgan Holdings, AptarGroup |

| Tier 2 | Precision Valve Corporation, Summit Packaging Systems, Lindal Group |

| Tier 3 | Coster Group, Mitani Valve, KOH-I-NOOR Mladá Vožice, Plastipak |

Leading manufacturers enhance AI-driven production, sustainable materials, and smart dispensing technology. They integrate lightweight, tamper-proof features to improve safety and durability. Companies develop cloud-based defect detection systems to optimize manufacturing efficiency. Manufacturers adopt predictive analytics to anticipate defects and improve quality control. They implement energy-efficient production processes to reduce carbon emissions and operational costs.

| Manufacturer | Latest Developments |

|---|---|

| Berry Global | Expanded biodegradable cap production (March 2024) |

| Silgan Holdings | Developed tamper-resistant child-safe caps (April 2024) |

| AptarGroup | Introduced custom ergonomic designs (May 2024) |

| Precision Valve Corporation | Released AI-powered defect detection (June 2024) |

| Summit Packaging Systems | Innovated smart dispensing technology (July 2024) |

| Lindal Group | Strengthened recyclable cap manufacturing (August 2024) |

| Coster Group | Enhanced pharmaceutical packaging solutions (September 2024) |

The aerosol cap market evolves as companies invest in automation, smart materials, and sustainable packaging. Firms integrate AI-driven defect detection, lightweight materials, and tamper-proof features to improve product safety and efficiency. Companies enhance production speed by adopting high-precision molding technologies. They implement biodegradable and compostable materials to reduce environmental impact.

Manufacturers develop AI-driven customization, ultra-lightweight materials, and tamper-proof packaging. They refine recyclable and biodegradable caps while integrating IoT-enabled smart dispensing solutions to enhance functionality and reduce waste. Companies improve material durability to withstand various environmental conditions. They incorporate 3D printing techniques to accelerate prototype development and production. Firms optimize injection molding processes to increase precision and reduce material waste. Manufacturers integrate antimicrobial coatings to enhance product safety. Businesses leverage digital tracking systems to improve supply chain transparency and reduce counterfeiting. Companies adopt AI-powered demand forecasting to optimize production planning and reduce excess inventory.

Berry Global, Silgan Holdings, AptarGroup, Precision Valve Corporation, Summit Packaging Systems, Lindal Group, Coster Group, Mitani Valve, KOH-I-NOOR Mladá Vožice, Plastipak.

The top 3 players collectively hold 17% of the global market.

The market shows medium concentration, with top players holding 37%.

Companies are developing biodegradable and recyclable materials, integrating AI-driven defect detection, and enhancing tamper-proof designs to improve safety and sustainability.

Nitrogen Flushing Machine Market Analysis by Automatic and Semi-Automatic Through 2035

Pan Liner Market Analysis by Polyethylene (PE), Nylon, Polypropylene, Polyester, Polytetrafluoroethylene (PTFE) and Biodegradable Plastics Through 2035

Perfume Filling Machine Market Analysis by Automatic Perfume Filling Machines and Manual Perfume Filling Machines Through 2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Packaging Tensioner Market Analysis - Growth & Forecast 2025 to 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.