The 3D printed packaging market is evolving at a very fast pace as businesses are utilizing additive manufacturing for customized, light-weight, and eco-friendly packaging. Businesses are implementing cutting-edge 3D printing techniques like multi-material printing, bio-based polymers, and AI-optimized design to gain higher productivity and lower waste.

In response to industry requirements, companies are embracing digital twin technology, high-speed 3D printing methods, and automation of post-processing for affordable, mass-producible manufacturing. The market is gravitating towards green, high-strength, and customized packaging that adheres to stringent sustainability standards in the food, pharmaceuticals, and consumer goods sectors.

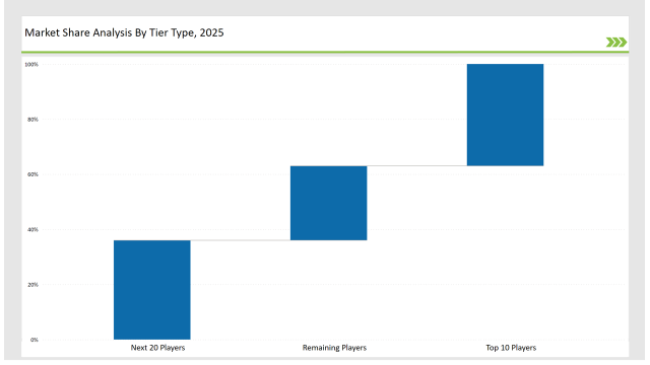

Tier 1 players like HP Inc., Stratasys, and 3D Systems control 37% of the market with their industrial-grade 3D printers, material technology, and international distribution networks.

Tier 2 players such as Materialise, EOS GmbH, and Markforged capture 36% market share with their offering of high-precision printing technologies, mass customization solutions, and developed material formulations for packaging solutions across industries.

Tier 3 is comprised of regional and niche players that have expertise in biodegradable packaging, AI-generated generative packaging designs, and localized production, which together occupy the remaining 27% of the market.

Explore FMI!

Book a free demo

Global Market Share by Key Players (2025)

| Category | Market Share (%) |

|---|---|

| Top 3 (HP Inc., Stratasys, 3D Systems) | 19% |

| Rest of Top 5 (Materialise, EOS GmbH) | 11% |

| Next 5 of Top 10 (Markforged, Carbon, Desktop Metal, Xometry, Proto Labs) | 7% |

The 3D printed packaging industry supports various sectors through innovation in lightweighting, sustainability, and mass customization. Companies employ next-gen 3D printing technologies to improve production scalability and packaging functionality. Businesses are integrating AI-driven design tools to optimize packaging structures. They are also experimenting with bio-based 3D printing materials to enhance sustainability.

Manufacturers are expanding their capabilities with AI-driven generative design, automated mass customization, and sustainable 3D printing materials. Companies are leveraging AI-powered simulations to optimize material usage and reduce waste. Smart packaging is emerging as firms integrate embedded RFID and NFC chips into 3D-printed structures.

Automation and AI-driven design reshape the 3D printed packaging market. Businesses optimize production by integrating AI-powered packaging simulations, cloud-based printing farms, and robotic post-processing solutions. Companies enhance packaging security with embedded authentication technology and forensic-level serialization. Firms develop self-learning AI systems to improve design efficiency. They implement digital twin technology for real-time monitoring and predictive maintenance. Companies create lightweight, high-strength packaging with AI-driven structural optimization. Industry leaders innovate with bio-based polymers to boost sustainability.

Year-on-Year Leaders

Technology providers must aim at AI-facilitated mass customization, use of recyclable materials, and digital twin-enabled manufacturing productivity. Alignment with industries like pharma, food, and high-end goods will help accelerate the pace of adoption and innovation.

| Tier Type | Example of Key Players |

|---|---|

| Tier 1 | HP Inc., Stratasys, 3D Systems |

| Tier 2 | Materialise, EOS GmbH, Markforged |

| Tier 3 | Carbon, Desktop Metal, Xometry, Proto Labs |

Leading manufacturers lead 3D-printed packaging innovation with AI-optimized material selection, lightweight structural design, and sustainable production processes. Companies integrate tamper-proof serialization and embedded authentication in 3D-printed packaging to enhance security and supply chain transparency. Companies are also exploring self-healing materials to improve packaging longevity and reduce waste.

| Manufacturer | Latest Developments |

|---|---|

| HP Inc. | Released industrial-scale 3D packaging printers in March 2024. |

| Stratasys | Launched multi-material food-safe 3D-printed packaging in April 2024. |

| 3D Systems | Introduced bio-based polymer packaging solutions in May 2024. |

| Materialise | Expanded cloud-based AI design tools in June 2024. |

| EOS GmbH | Strengthened biodegradable polymer capabilities in July 2024. |

| Markforged | Pioneered metal-infused 3D-printed security packaging in August 2024. |

| Carbon | Innovated sustainable lattice-based packaging in September 2024. |

Manufacturers are revolutionizing the 3D printed packaging industry by investing in AI-driven generative design, sustainable materials, and real-time digital twin simulation. They are optimizing packaging security with embedded authentication chips and blockchain-backed track-and-trace systems. Companies are expanding the use of machine learning algorithms to predict and prevent supply chain disruptions. They are also integrating temperature-sensitive tracking labels to monitor storage conditions and ensure product integrity.

Manufacturers will enhance AI-driven packaging design, integrate sustainable 3D printing materials, and expand real-time authentication technologies. Companies will adopt fully automated, digital twin-enabled production lines for scalable, high-efficiency packaging manufacturing. Smart packaging will enable real-time consumer engagement through 3D-printed embedded tracking technology. Businesses will develop forensic-level security printing for anti-counterfeit measures. Companies will expand predictive analytics for supply chain optimization. Firms will incorporate IoT-enabled sensors into 3D-printed packaging. Manufacturers will refine biodegradable materials for high-performance sustainable packaging.

Leading players include HP Inc., Stratasys, 3D Systems, Materialise, EOS GmbH, and Markforged.

The top 3 players collectively hold 19% of the global market.

The market shows medium concentration, with the top players holding 37% of the industry share.

Key drivers include AI-driven generative design, eco-friendly materials, digital twin technology, and automation in 3D-printed packaging production.

Nitrogen Flushing Machine Market Report – Trends, Size & Forecast 2025-2035

Pan Liner Market Insights – Demand, Growth & Industry Trends 2025-2035

Perfume Filling Machine Market Report – Trends, Demand & Industry Forecast 2025-2035

Molded Pulp Packaging Machines Market Analysis - Growth & Forecast 2025 to 2035

Packaging Tensioner Market Analysis - Growth & Forecast 2025 to 2035

Packaging Films Market Analysis by Product Type, Material Type and End Use Through 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.